Drip Meter Model NDR-6

- 8mm

This meter complies with JIS technical standards for specific measuring instruments.

Capable of measuring ultra low flow rate of 0.1L/h.

Low pressure loss eliminates the need for pumping.

No leakage due to the use of a magnetic coupling for counter transmission.

Since it is a standalone internal type, dust and air can be discharged through the drain outlet.

Pulse rate of the pump with transmitter (model GNDR-6) is 0.1L/P.

Please replace it after 5 years to maintain the performance.

Purpose of use

Measurement of kerosene consumption in housing complexes, etc.

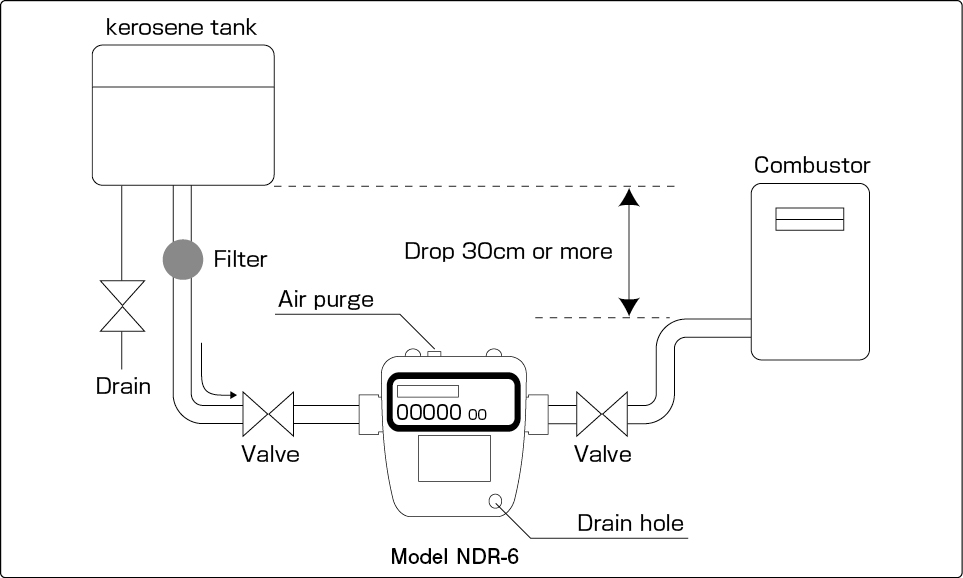

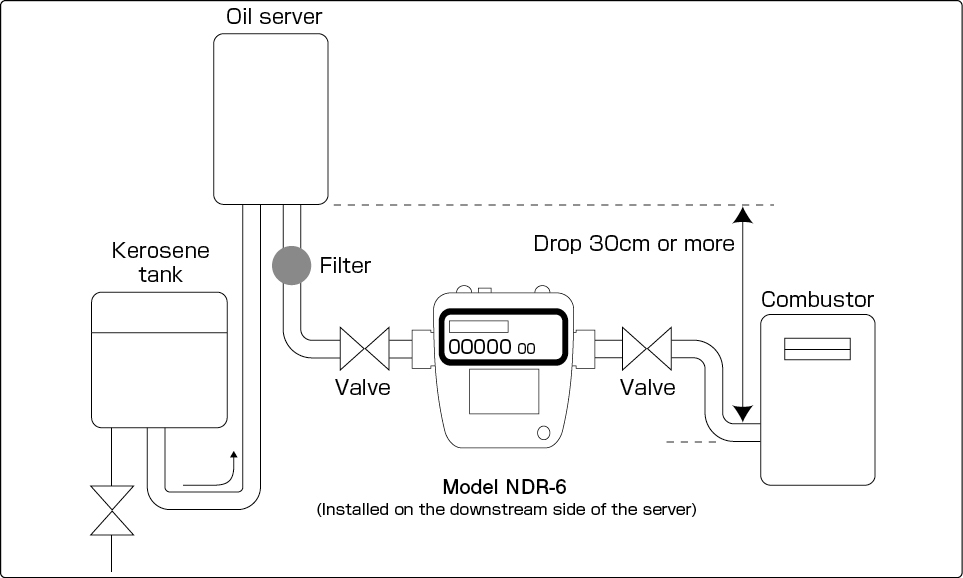

- (1) This meter operates with a natural drop-off. Please allow a drop of at least 30 cm between the kerosene tank and the combustor. If an oil server is attached, install the meter downstream of the server.

- (2) When pressurizing the piping to test for leaks, do so with the meter disconnected.

- (3) Install the filter.

- (4) Keep the inlet side valve open even when the meter is not in use.

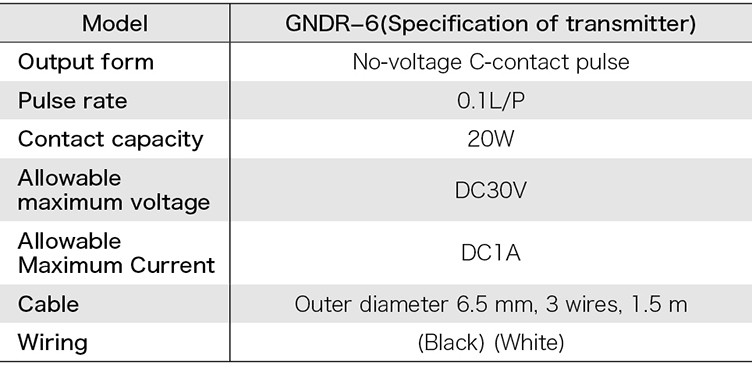

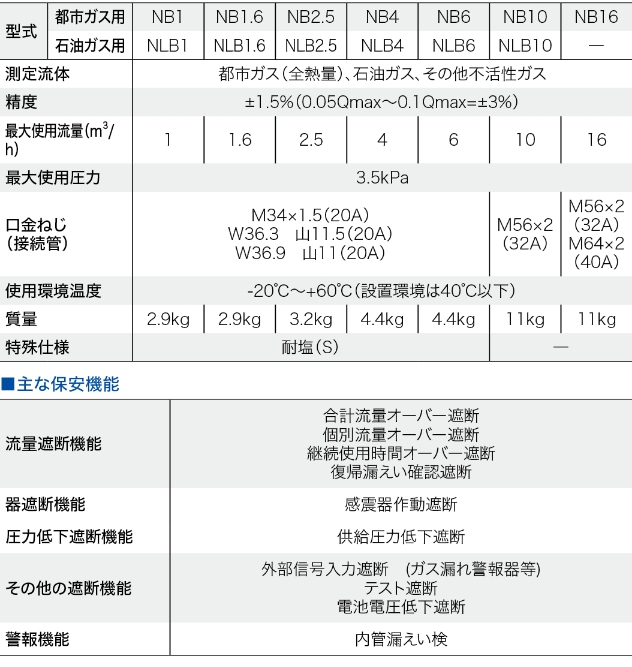

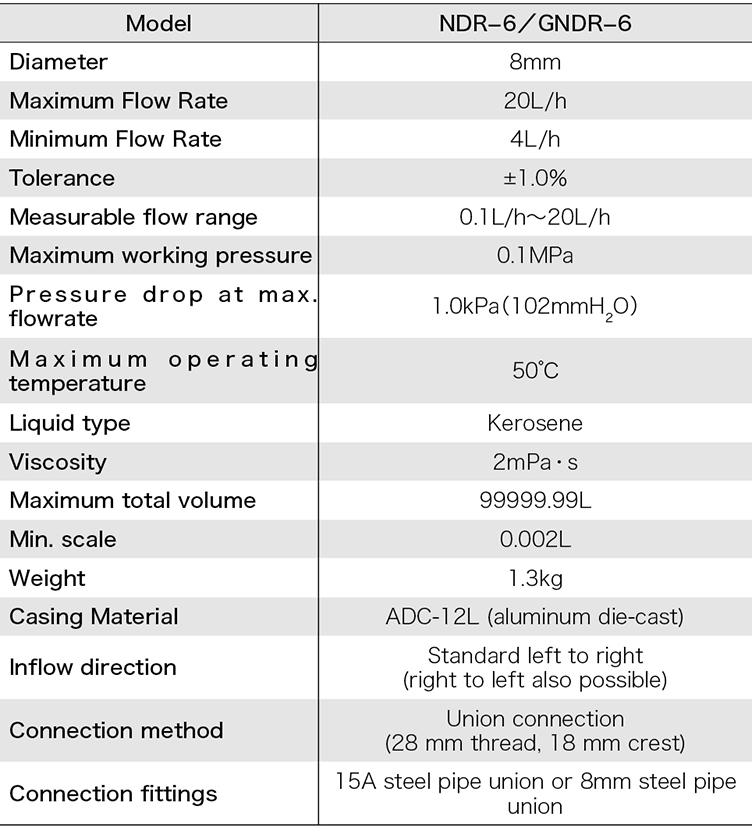

Specification

Click to enlarge

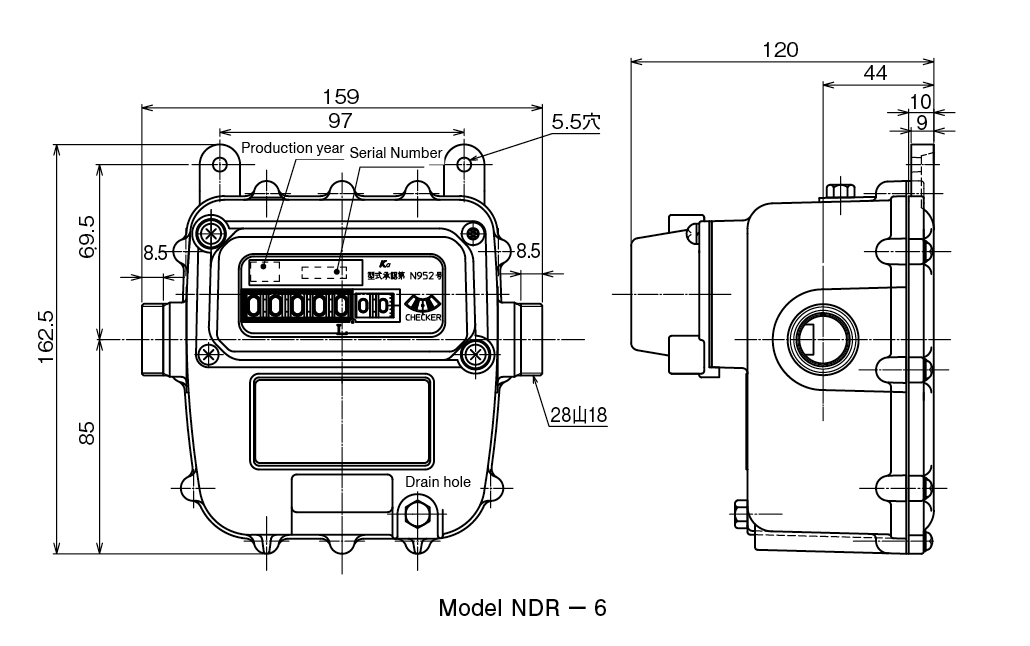

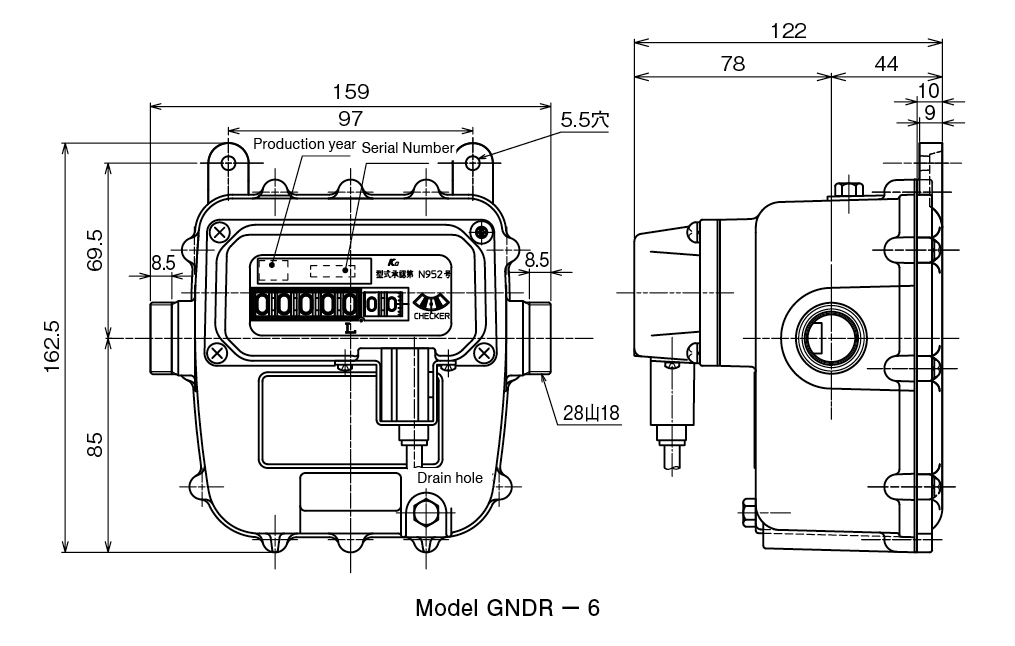

Main Dimensions and External Dimensions

Example of piping -1

Click to enlarge

Example of piping -2

Click to enlarge

- Make sure to place the kerosene tank so that its underside is at least 30 cm higher than the piping of the combustor.

Also, piping should be done in such a way that air does not accumulate. (Please also be sure to fully bleed the air inside the meter.)

→If the drop is insufficient or there is air accumulation, the meter counter may stop and kerosene may not be supplied. - When conducting a leakage test of piping, the applied pressure should be 0.1 MPa (1 kgf/cm2) or less. In addition, the test fluid should be pressurized and drained gradually so as not to exceed the maximum flow rate of 20 L/h.

→Sudden pressurization and discharge can damage the meter. - Install the meter so that it is level and the counter faces the front, paying attention to the entrance and exit.

→Accurate measuring may not be possible. - Do not close both inlet and outlet valves of the meter except for maintenance.

→If the temperature inside the meter rises in a sealed condition, the meter may break or leak due to increased pressure.

We recommend installing a strainer (100 mesh or more) or similar device to prevent foreign matter such as dust or rust from entering the meter. - Also, drain the meter on a regular basis.

→Contamination of foreign matter or moisture may cause meter performance degradation or immobility.

- Please read the instruction manual before handling the meter.